Die Surface Designer

Automated Die Addendum Creation

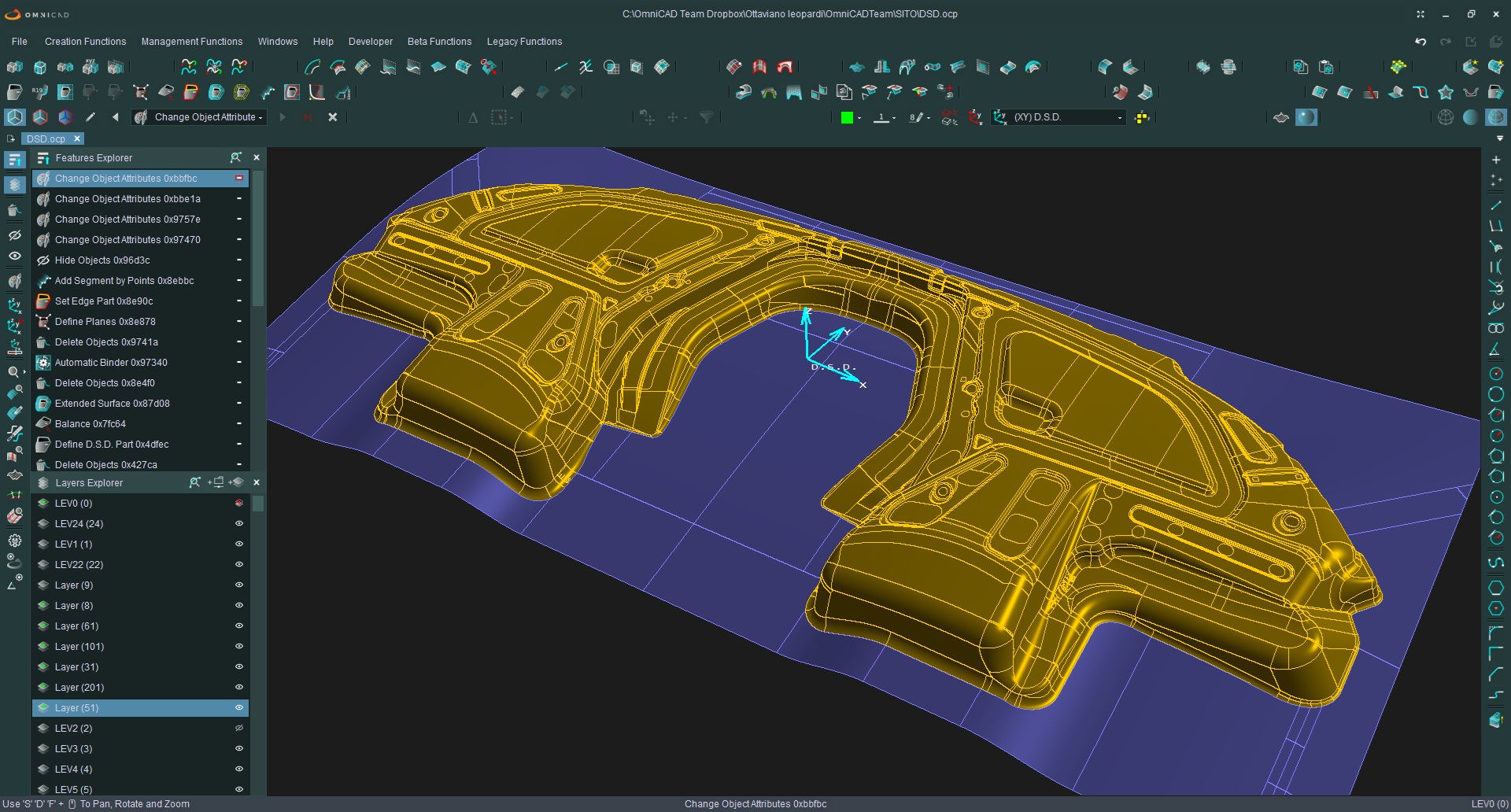

From Part to Production-Ready Die — Automated

Die addendum design is one of the most time-consuming stages in tooling engineering. Die Surface Designer automates it entirely — generating production-ready die surfaces in a fraction of the time it takes manually.

Every element is built parametrically. Change your input part geometry, and the entire die surface chain — from binder to addendum walls — regenerates automatically. Combined with direct JSTAMP CAE integration, you can validate and iterate designs without switching tools or transferring data.

Request DemoCore Features

- ✓ End-to-end die addendum automation

- ✓ Parametric regeneration on geometry changes

- ✓ Direct JSTAMP CAE integration

- ✓ Intelligent binder and balance optimization

- ✓ Production-proven across major OEMs

See Die Surface Designer in Action

Complete die addendum creation for a door panel: automatic binder generation, part orientation balancing, surface extension with custom blending, addendum walls with variable fillets, and fill hole functionality for complex die surfaces.

Seamless CAE Integration

JSTAMP Integration

OmniCAD has developed a dedicated integration framework connecting Die Surface Designer with JSOL's JSTAMP simulation software.

This powerful combination creates a seamless CAD-to-CAE workflow for die design validation. Transfer die surface geometry directly to JSTAMP for simulation, receive feedback, and apply compensations—all within a unified workflow.

Integration enables:

- ✓ Direct geometry transfer to JSTAMP

- ✓ Simulation feedback integration

- ✓ Rapid design-validation iteration

- ✓ Reduced die tryout cycles

JSOL Corporation, our partner in Japan, provides JSTAMP—a leading sheet metal forming simulation solution. Learn more about JSTAMP

Automate your die design workflow

See Die Surface Designer create production-ready addendum surfaces.